CIMCO Machine Simulation

CIMCO Machine Simulation – The Complete CNC Machining Simulation Solution

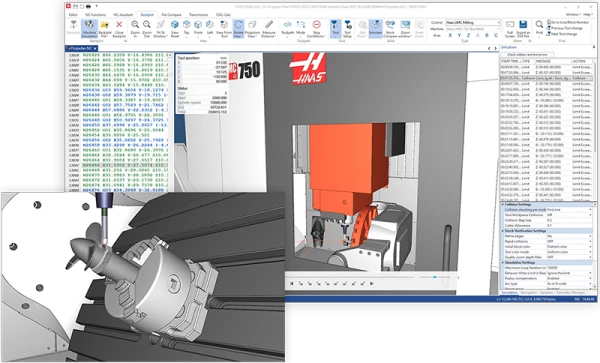

CIMCO Machine Simulation provides a comprehensive range of features that ensure complete NC code simulation in a 3D machine environment. Designed to complement the CIMCO Edit software, this add-on allows for dynamic analysis of CNC machining paths with a variety of simulation tools. The interface, familiar from video playback programs, makes it intuitive and user-friendly, allowing for simulation viewing from different angles and distances with zoom, pan, and rotate features.

Confidence and Efficiency with Simulation

CIMCO Machine Simulation helps eliminate costly programming errors and speeds up deployment by providing a cost-effective and easy-to-use CNC machine simulation solution. By simulating NC programs in three-dimensional machine setups, you can accurately view the movements of components, such as rotating heads and spindles, as well as supporting devices. Collisions and boundary breaches are automatically detected, ensuring that error-free code is sent to the physical machine.

- Machining Safety: Protect personnel and machinery from hazardous situations by simulating and testing your NC programs on a computer before running them on physical machines.

- Faster Deployment: Reduce the time spent on starting and calibrating work. Once the NC program has been thoroughly simulated on the computer, it can be confidently run on the first try.

- Quick Changes and Optimization: Optimize your programs by quickly testing new ideas and changes on the computer. You save time, resources, and machine tool wear and can smoothly transition between machine configurations.

CIMCO Simulation and NC Program Editing

CIMCO Machine Simulation combines simulation and NC editing into a fully integrated solution, which is an efficient way to quickly simulate and fix code issues. By using the simulation's 3D functions, you can train employees in using machine tools and editing NC code before physical testing.

- Full Simulation Control: Analyze your NC program simulation from any angle or distance by zooming, panning, and rotating the view. An adjustable speed slider in both directions and the option to move to the next/previous tool change, break line, or movement.

- Stock and Geometry Management: You can define the stock, upload STL files of the workpiece, fixtures, and other parts. The resulting stock can be exported as an STL file for further processing.

Monitoring and Inspection

CIMCO Machine Simulation offers a concurrent view of NC code, simulation, and simulation report. During simulation, parts causing collisions are automatically highlighted. Collisions, boundary breaches, and program errors are detected and reported in the simulation report. This feature facilitates error identification and correction, improving programming quality.

Simulation Report: The automatic simulation report provides a detailed list of all the errors in your NC program. Select any reported error and jump directly to the line causing it. Edit the NC code, and the simulation report updates, allowing you to immediately see if the problem is resolved.

Machine Configuration and Integration

Load and install pre-configured machines directly into the CIMCO Machine Simulation program, or build your own with the Machine Configuration Editor tool. You can also seamlessly integrate tools, holders, and geometry from Mastercam or other CAM systems into the Machine Simulation program. This capability eases managing changes in the CAM system and updating them in simulation or backplot functions.

CIMCO Machine Simulation is a solution that elevates your industry's simulation and quality assurance to a new level. Providing you with tools to enhance production efficiency and confidence without unnecessary programming errors, you can take the next step towards smoother and safer production.